Developing an electronic product involves multiple stages, each with distinct technical and financial requirements. For budget-friendly projects, costs can be as low as $20,000, while complex industrial products can surpass $300,000. Generally, electronic product development ranges between $20,000 and $120,000, depending on functionality, market requirements, and production goals.

Let’s break down each major stage and their respective development costs.

Key Stages and Costs of Electronic Product Development

1. Project Management ($2,000 – $20,000)

Effective project management is foundational for a successful product launch. This stage includes organizing timelines, managing technical decisions, and allocating resources to ensure every step aligns with the project’s objectives. Skilled project managers prevent costly delays by coordinating cross-functional teams, resolving potential issues, and maintaining open communication among all stakeholders.

For projects requiring high precision or significant cross-departmental collaboration, investing in project management can maximize quality and reduce the risk of misalignment as the project progresses.

2. System Design ($1,000 – $10,000)

System design shapes the architecture of the product, focusing on balancing cost, performance, and reliability. This stage brings together experienced engineers to define the integration of software, mechanical, and electrical components, essentially outlining how the product will function as a cohesive system.

Key deliverables include system diagrams, specifications, and initial assessments of component compatibility, which form the foundation for subsequent design stages. Depending on the complexity and required functionality, system design costs can vary, but thoughtful planning here helps to avoid expensive redesigns later on.

3. Industrial Design ($0 – $20,000)

For consumer-facing products, industrial design is essential. This stage focuses on creating a visually appealing and ergonomic product that resonates with users. Effective industrial design can elevate user experience, make the product more marketable, and even impact production costs if done efficiently.

This stage is especially important for products that require a strong aesthetic appeal or alignment with current market trends, though not every project will need an in-depth design process. Industrial design can range widely in cost, particularly if extensive prototyping or design iterations are required.

4. Mechanical Design ($3,000 – $40,000)

Mechanical design translates conceptual inputs into detailed, manufacturable plans. Engineers use CAD tools to develop precise dimensions, select materials, and outline assembly requirements, creating a blueprint that transforms design ideas into a tangible product. Testing design integrity is crucial to ensure the product can withstand real-world conditions.

Mechanical design costs depend on the complexity of the parts and materials used, especially if durability, size, or specific mechanical functions are required. Investing in thorough mechanical design ensures that the product can scale efficiently in manufacturing.

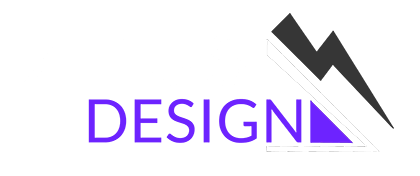

5. Electronics Hardware Design ($4,000 – $50,000)

At the heart of any electronic product is the printed circuit board (PCB), which houses essential electronic components. Hardware design covers everything from selecting components to creating the PCB layout and minimizing electrical interference. The level of functionality, power requirements, and physical constraints affect the hardware design’s complexity.

Higher complexity requires more time in designing, testing, and refining, impacting overall costs. Thoughtful hardware design is essential for seamless integration and minimizing the risk of post-production issues.

6. Firmware Development ($4,000 – $100,000)

Firmware enables the device to operate as intended, from basic functionalities to complex interactions with other devices or software. Development costs depend on functionality requirements—basic operations are generally lower in cost, while high-performance or IoT devices need more sophisticated firmware, raising the cost.

Testing, debugging, and optimizing firmware to ensure it works efficiently with the hardware also play a large role in cost. For smart products, firmware development often becomes one of the most significant cost components.

7. Web App Development for IoT ($0 – $50,000)

For Internet of Things (IoT) devices, web apps are critical for remote control and data interactions. Web app development costs vary based on the app’s complexity, required features, and security needs. Full-stack developers work on both the front and back ends, ensuring the app is user-friendly and responsive. For some products, particularly those targeted at consumer markets, this investment is essential to enhance user experience and differentiate the product in a competitive landscape.

8. Mobile App Development ($0 – $100,000)

Mobile apps are vital for IoT devices that need to interact with users through smartphones or tablets. This development stage involves creating iOS and Android compatibility, with a focus on usability, responsiveness, and data security. Costs vary depending on required features, UI/UX complexity, and ongoing maintenance. For consumer electronics, a well-designed mobile app can significantly improve product appeal and usability, making it a worthwhile investment for IoT projects.

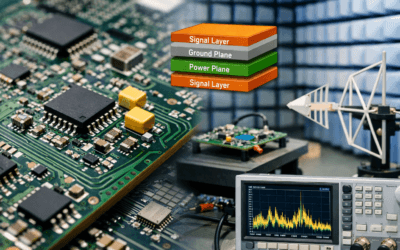

9. Prototyping ($1,000 – $10,000)

Prototyping allows teams to consolidate design ideas and test the product’s functionality in a tangible form. Early prototypes reveal design flaws, helping to refine the product before mass production. Prototyping costs vary based on the number of iterations needed and the materials used, but identifying issues at this stage is far less costly than adjusting large-scale production. This stage provides critical insights into functionality, ensuring the product meets performance expectations and is ready for the next step.

Mass Production Preparation and Industrialization Costs

1. Validation Testing ($2,000 – $20,000)

Validation testing is critical for preparing the product for mass production, ensuring it functions as intended. Engineers typically conduct various validation stages, including engineering validation testing (EVT), design validation testing (DVT), and production validation testing (PVT).

Some validation stages are handled in-house, while others may be outsourced to third-party contract manufacturers for added quality assurance. This process identifies any final issues, making it a crucial investment for product reliability and user satisfaction.

2. Injection Moulding ($2,000 – $40,000)

Injection moulding enables the efficient mass production of plastic parts, making it ideal for consumer electronics. This process is far more cost-effective for large runs than 3D printing and yields high-quality, consistent parts. Initial tooling costs may be high, but the per-unit cost drops significantly with higher production volumes. Injection moulding provides scalability for products requiring durable plastic components, making it essential for consumer electronics with large production demands.

3. Certification and Approval ($0 – $50,000)

Many electronic products require certifications to comply with standards such as FCC, UL, CE, and RoHS, which ensure safety, performance, and environmental responsibility. The cost of certification varies depending on the product’s complexity and market requirements. Working with certified testing labs ensures compliance and reduces the risk of delayed market entry. For products targeting international markets, meeting these standards is often a non-negotiable investment in brand credibility and legal protection.

4. Product Packaging ($0 – $10,000)

Packaging design is more than just a functional necessity—it impacts branding and user perception. For consumer-facing products, well-designed packaging creates a memorable unboxing experience, reinforcing brand identity and adding perceived value. Packaging costs can vary widely based on material choices, design complexity, and the target market’s expectations. Thoughtful packaging design distinguishes a product in the market, making it an integral part of the development budget for products aimed at end consumers.

Zeus Design’s Expertise in Cost-Efficient Product Development

At Zeus Design, we specialize in guiding electronic product development projects with a focus on cost efficiency and precision. Our team has experience managing projects across a wide spectrum, from budget-friendly hardware solutions to complex industrial equipment, allowing us to scale solutions according to each client’s goals and budget. By addressing every stage from system design to certification, we help clients navigate each cost factor thoughtfully, achieving both functionality and quality.

If you’re planning an electronic product design and looking to balance cost with performance, Zeus Design can tailor a development plan to meet your needs, ensuring each phase supports your product vision.

Final Thoughts

Electronic product development requires a comprehensive understanding of costs across each stage, from system design to packaging. Managing these expenses thoughtfully ensures a high-quality, market-ready product that aligns with business objectives. By breaking down these cost factors and preparing for each development stage, you can make informed decisions that benefit your product and your bottom line.For more guidance on aligning your product with budget and performance goals, contact Zeus Design and bring your vision to life.

0 Comments