Artificial intelligence (AI) is transforming industries around the world, bringing unprecedented efficiency, innovation, and automation to processes across various sectors. In the realm of electronics design, AI is increasingly being recognised for its ability to revolutionise workflows, enhance decision-making, and optimise performance. From automating complex design processes to predicting potential system failures, AI is reshaping how electronics are developed and manufactured.

With growing demands for smarter, faster, and more reliable electronic devices, AI has the potential to unlock new levels of innovation in electronics design. This article explores the key areas where AI is making an impact and discusses the challenges and future opportunities for AI-powered electronics.

Key Areas of Impact of AI in Electronics Design

AI is a game changer in the electronics design industry, streamlining processes that traditionally required intensive manual effort, reducing design cycles, and enabling more sophisticated products. Below, we dive into the core areas where AI is driving significant advancements.

Circuit Design and Optimisation

Circuit design is a foundational element in electronics, and AI is helping to enhance every stage of this process—from the early conceptual design phase to optimisation during production. AI-driven tools help engineers simulate and test circuits under various conditions, ensuring that circuits meet both performance and safety standards before they are physically built.

Circuit Simulation and Performance Testing

AI-powered tools enable real-time simulation of electronic circuits, allowing designers to identify potential issues early in the design phase. Traditional circuit simulation often involves time-consuming trial-and-error processes, but with AI, designers can predict circuit behaviour under different operational conditions and loads. AI can also spot inefficiencies, suggest design improvements, and predict system failures, thereby improving overall reliability and performance. By analysing circuit behaviour dynamically, AI provides insights into potential challenges like signal interference, heat dissipation issues, and voltage drops.

Circuit Design Optimisation

AI can significantly improve the optimisation of circuit designs. AI algorithms assist in selecting the best components, enhancing signal integrity, and reducing power consumption. Leveraging historical design data, AI learns from past mistakes and successes, which allows it to suggest improvements that enhance overall circuit performance. This could mean re-routing traces, resizing components, or recommending alternative configurations that lower power usage and extend device lifespan. AI’s ability to balance multiple factors—such as performance, cost, and energy efficiency—makes it an invaluable tool for designing optimised circuits.

Tools for Circuit Design Automation

AI-driven computer-aided design (CAD) tools are revolutionising the electronics industry by automating many aspects of circuit design. These platforms, such as Altium Designer, Mentor Graphics, and Cadence, integrate AI to handle repetitive tasks, streamline design processes, and optimise layouts, improving productivity and reducing human error. AI-powered CAD tools not only reduce manual input but also make real-time suggestions to designers, enhancing precision and reducing the likelihood of errors. AI is enabling faster iterations and helping designers meet tight deadlines without sacrificing quality or performance.

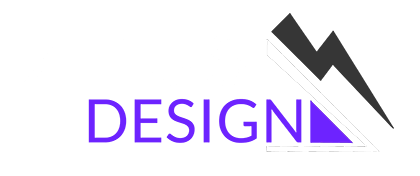

PCB Design and Prototyping

Printed circuit boards (PCBs) form the backbone of most electronic devices, and AI is transforming how PCBs are designed, reducing time to market, and enhancing reliability. AI helps in automating the layout of components, ensuring more efficient routing of electrical paths while taking into account manufacturability and performance factors.

Automating PCB Layout

AI-based algorithms automate the arrangement of components on PCBs, ensuring optimal placement for performance, cooling, and manufacturability. Traditional PCB layout processes can be laborious, with designers manually positioning hundreds, if not thousands, of components to ensure efficient routing and heat management. AI significantly reduces the time spent on layout iterations, allowing for faster prototyping and product development. AI-driven PCB design tools analyse the schematic and suggest the best placement of components to minimise cross-talk, reduce heat spots, and optimise routing paths.

Improving PCB Manufacturing

AI optimises PCB designs for manufacturability, taking into account factors like material selection, production techniques, and tolerance levels. This helps reduce errors during the production process, ensuring that PCB designs are aligned with manufacturing capabilities. AI can also adapt designs to meet specific manufacturing constraints, such as selecting materials that are easier to source or minimising the number of layers to reduce costs. The result is a more efficient manufacturing process, with fewer reworks and less waste.

Component Selection and Supply Chain Management

Component selection and supply chain logistics are critical factors in the success of any electronic product. AI is streamlining these processes by providing real-time insights into component performance, availability, and cost.

Component Selection Through AI Algorithms

AI algorithms analyse component databases to suggest the best options based on specific design requirements, such as power consumption, size, and durability. This ensures that designers can make more informed decisions and choose components that are best suited for the intended application.

AI-Optimised Supply Chain Management

AI is also transforming supply chain management by predicting component shortages, analysing cost trends, and recommending alternative suppliers. Predictive analytics allow manufacturers to anticipate disruptions and adjust their inventory strategies accordingly, ensuring timely production and delivery.

Enhancing Testing and Quality Assurance

AI plays a pivotal role in automating the testing and quality assurance processes, ensuring that electronics meet the highest standards before they reach the market.

Real-Time Testing and Defect Detection

AI-driven systems can continuously test electronic circuits in real time, detecting defects or performance issues as they occur. By using machine learning algorithms to analyse test data, AI can identify patterns that may indicate potential faults, enabling quicker troubleshooting.

Automating Quality Assurance

By automating quality assurance, AI reduces the need for manual testing, significantly cutting down the time required to validate a design. AI systems can check for compliance with design rules, ensure component functionality, and flag inconsistencies before the production phase.

AI in Predictive Maintenance and Failure Prediction

One of the most powerful applications of AI in electronics is its ability to predict when systems are likely to fail and provide maintenance recommendations.

AI-Driven Failure Prediction in Electronics Systems

AI systems can analyse historical performance data and usage patterns to predict when a component or system might fail. By detecting anomalies in real-time data, AI algorithms can alert designers or maintenance teams to potential problems before they escalate into full-blown failures.

Predictive Maintenance

AI-based predictive maintenance systems notify teams when components are approaching their end-of-life or require maintenance. This proactive approach helps avoid costly downtime and extends the life of electronic devices, contributing to overall cost savings.

Challenges of Integrating AI in Electronics Design

While AI offers vast potential in electronics design, integrating AI-driven solutions comes with its own set of challenges.

High Costs

Implementing AI tools and platforms requires significant upfront investment. The cost of acquiring AI-powered software, setting up infrastructure, and training personnel can be prohibitive, especially for small and medium-sized businesses.

Technical Complexity

AI solutions often require specialised knowledge to implement and manage. The complexity of integrating AI into existing design processes can be a barrier, especially for companies that lack experience with advanced technologies.

Data Availability and Quality

AI systems rely heavily on data to make accurate predictions and decisions. A lack of sufficient, high-quality data can limit the effectiveness of AI in electronics design, as the algorithms need vast datasets to learn and improve.

Overcoming Integration Challenges with AI

Despite the challenges, the industry is finding ways to make AI integration easier. The rise of more accessible AI platforms and the increasing availability of AI education are helping to bridge the gap. Companies are investing in AI training for their teams and adopting cloud-based AI solutions, which reduce the need for expensive infrastructure. Additionally, AI tools are becoming more user-friendly, lowering the technical barrier to entry.

The Future of AI in Electronics Design

The future of AI in electronics design is incredibly promising. As AI technologies continue to evolve, they will become even more integral to the development of complex electronics systems. Emerging trends include deeper integration of AI into the entire design and manufacturing lifecycle, from concept generation to final production.

AI-powered tools will likely continue to enhance collaboration between human designers and machines, where AI handles routine tasks, allowing designers to focus on creativity and innovation. As AI becomes more adept at processing data, we can expect more sophisticated optimisation algorithms, improving everything from component selection to energy efficiency.

Additionally, advancements in AI-driven simulations and virtual prototyping will reduce the need for physical prototypes, cutting costs and accelerating time to market. The integration of AI with other technologies, such as the Internet of Things (IoT) and 5G, will further transform how electronics are designed, tested, and maintained, making products smarter and more adaptive.

Conclusion

AI is revolutionising the electronics design industry by driving innovation, enhancing efficiency, and optimising processes at every stage of the design and manufacturing process. From circuit and PCB design to component selection and predictive maintenance, AI’s role in electronics design is becoming indispensable.

As the technology matures, AI will continue to open new doors for innovation, improving how electronics are created, tested, and maintained. Companies that adopt AI-driven tools and strategies will be better positioned to lead in an increasingly competitive market.

Zeus Design: Pioneers in AI-Powered Electronics Design

At Zeus Design, we embrace the power of AI to deliver cutting-edge electronics design solutions. Our team utilises AI-driven tools and techniques to optimise every stage of the design process—from circuit design and PCB prototyping to component selection and testing. Learn more about how our electronics design services can help you bring smarter, more efficient products to market.

0 Comments