Introduction to Thermal Management in Electronics

Understanding the Basics

Thermal management in electronics design isn’t just a technical necessity; it’s the art of keeping your gadgets cool under pressure. Imagine your electronics are athletes running a marathon. Just like these athletes need strategies to prevent overheating, electronics require thermal management to operate efficiently. Without it, we’re looking at a sprint to system failure rather than a victory lap of longevity and reliability.

Why Thermal Management is Crucial for Electronics

Why, you ask, does this matter? Well, at the heart of every piece of tech you love – from the smartphone in your pocket to the laptop you rely on – there’s a PCB (printed circuit board) that functions much like the nervous system in the human body. This PCB, crammed with components, generates heat. Without proper thermal management, this heat can lead to reduced performance, reliability issues, and a shorter lifespan for your beloved devices. Essentially, good thermal management in electronics design ensures your gadgets don’t sweat under stress, keeping them cool, calm, and collected.

The Impact of Heat on Electronics Performance

Thermal Challenges in Modern Electronics

Modern electronics are pushing the boundaries of performance, packing more power into smaller packages. But with great power comes great thermal challenges. It’s like trying to run a high-speed train on tracks designed for a leisurely journey. The heat generated can derail performance, causing everything from temporary glitches to complete system meltdowns. Managing this heat effectively is not just beneficial; it’s critical for the advancement of technology.

Case Studies: When Heat Management Fails

We’ve all heard the tales or perhaps even experienced the dreaded device shutdown due to overheating. These aren’t just minor inconveniences; they are real-world lessons in the importance of thermal management. From smartphones that feel too hot to hold, to laptops that shut down during a crucial presentation, these examples highlight the tangible impacts of heat on electronics performance. It’s a clear reminder that effective thermal management is essential for keeping our digital lives running smoothly.

Fundamental Principles of Thermal Management

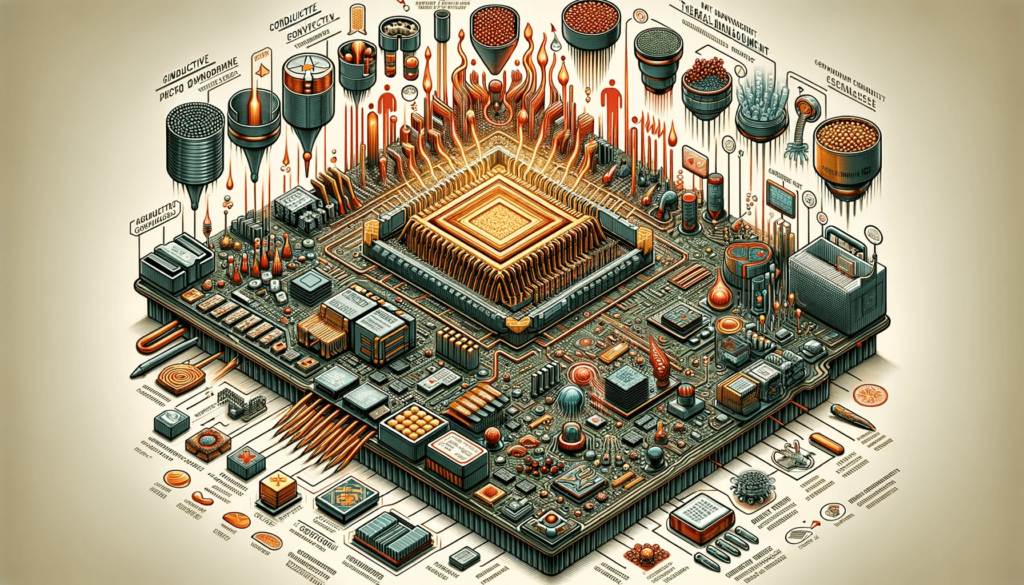

Conductive, Convective, and Radiative Heat Transfer

Diving into the science of thermal management, we find three musketeers of heat transfer: conduction, convection, and radiation. Conduction is the heat transfer through materials (think of a spoon getting hot in a pot of soup), convection involves the movement of heat through fluids (like a breeze cooling you on a hot day), and radiation means heat transfer through electromagnetic waves (similar to feeling the sun’s warmth). Electronics design leverages these principles to whisk away unwanted heat, ensuring devices stay cool under the electronic equivalent of a summer sun.

Materials and Technologies for Heat Dissipation

The quest for the Holy Grail in electronics design often leads to innovative materials and technologies for heat dissipation. From thermal vias that act as heat escape tunnels in PCBs, to advanced heat sinks that serve as mountains for heat to climb away from sensitive components, these solutions are the unsung heroes of electronics design. They ensure that the heat generated by our electronic marvels doesn’t end up cooking them from the inside out, allowing for sleeker, more powerful, and reliable devices.

Design Strategies for Effective Thermal Management

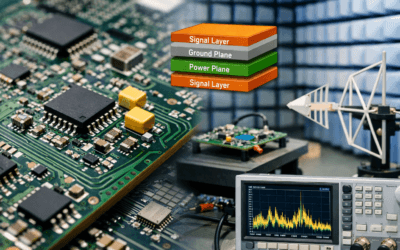

Incorporating Thermal Considerations into PCB Design

Think of PCB design like planning a city. Just as urban planners must consider ventilation and sun exposure to keep cities livable, electronics designers must integrate thermal considerations from the get-go. It’s about strategically placing components and utilizing materials that support heat dissipation. Imagine thermal vias as subway systems for heat, efficiently transporting it away from crowded component areas to cooler outskirts. This proactive approach not only keeps the electronic city from overheating but also enhances its inhabitants’ (components’) longevity and performance.

Heat Sinks, Thermal Vias, and Other Cooling Solutions

Heat sinks are the superheroes of the electronics world, swooping in to carry heat away with their capes of high thermal conductivity. Paired with thermal vias, which act like heat elevators moving through a PCB skyscraper, they form an effective duo against the nemesis of overheating. But the innovation doesn’t stop there. From liquid cooling systems that act like the electronics version of a splash in a pool, to Peltier devices that create a temperature difference on demand, the arsenal of cooling solutions is as varied as it is ingenious.

Thermal Simulation and Modeling in Design

Tools and Software for Thermal Analysis

Gone are the days of guesswork in electronics design. Today, we have an array of sophisticated software at our fingertips, offering a glimpse into the future of our designs. These tools are like time machines, allowing designers to simulate and visualize how heat moves through an electronic device, identifying hot spots and cooling inefficiencies before they become problems. It’s akin to weather forecasting for electronics, providing a chance to umbrella-proof designs against the stormy impacts of heat, ensuring they can weather any temperature.

Optimizing Designs for Heat Management

Optimization is the name of the game when it comes to marrying performance with thermal efficiency. It’s about finding that sweet spot where your device runs at peak performance without turning into a miniature volcano. Through iterative design and simulation, designers can tweak component placement, adjust materials, and experiment with cooling solutions. This process is like tuning an instrument, ensuring each note (or component) contributes to a harmonious symphony of efficient heat management and stellar performance.

Innovative Materials for Thermal Management

Advanced Composites and Alloys

The search for the perfect materials in electronics design feels like a quest in a fantasy novel, where each discovery has the potential to change the course of the story. Advanced composites and alloys, with their superior thermal properties, are the magic metals and mystic minerals of our tale. These materials don’t just conduct heat away; they redefine the boundaries of device design, allowing for thinner, lighter, and more powerful gadgets that can handle the heat of our expectations.

Nano-materials and Their Impact on Electronics Design

Enter the realm of nano-materials, where the tiny titans of technology offer colossal contributions to thermal management. These microscopic marvels, with their high surface area-to-volume ratios and exceptional thermal conductivities, are revolutionizing how we think about heat dissipation. Imagine a world where your device stays cool, not through bulky heat sinks, but through the magic of materials that operate on the atomic scale. This isn’t just the future of electronics design; it’s a glimpse into a cooler, more efficient world powered by the wonders of nano-technology.

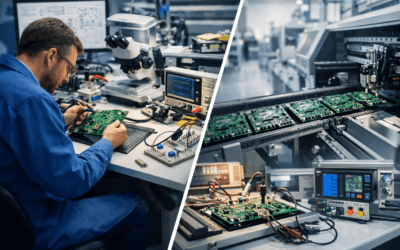

Case Study: Successful Thermal Management in Electronics

Analysis of a High-Performance PCB Design

Ever wonder how the latest smartphone in your hand manages to run cooler than its predecessors, despite packing a more powerful punch? Let’s dive into a case study of a high-performance PCB design that’s as cool as a cucumber. This particular design cleverly integrates heat sinks directly into the most critical areas, alongside thermal vias strategically placed to form a network of heat escape routes. It’s like having an intricate maze where heat is the runner, finding its way out at every turn. The result? A device that performs at its peak without breaking a sweat, showcasing the marvels of thoughtful thermal management.

Lessons Learned and Best Practices

The key takeaway from our case study? Anticipate, integrate, and innovate. By anticipating heat generation and integrating thermal management solutions right from the design phase, electronics can be engineered to dissipate heat more effectively. This approach not only enhances performance but also prolongs device longevity. Best practices include using simulation tools for heat mapping, choosing materials with excellent thermal properties, and never underestimating the power of a well-placed heat sink or thermal via. It’s a holistic strategy that keeps your electronics cool, no matter the heat they face.

The Role of Thermal Management in Device Reliability

Extending the Life of Electronic Components

Reliability in electronics isn’t just about performance today; it’s about endurance over time. Effective thermal management plays a pivotal role in this long-term reliability. Think of it as the difference between sprinting and running a marathon. Devices designed with heat in mind are the marathon runners, built to last the distance without overheating. By keeping components within their optimal temperature ranges, we significantly reduce the wear and tear caused by thermal cycling, thereby extending the life of electronic gadgets.

Ensuring Performance Under Extreme Conditions

Designing for extreme conditions is like preparing for the worst weather – you want to be ready for anything. Devices equipped with robust thermal management systems can withstand high temperatures and harsh environments, from the scorching heat of a desert to the confined spaces of automotive electronics. This resilience ensures that no matter where you are, your device won’t just survive; it’ll thrive, providing consistent performance when you need it most.

Future Trends in Thermal Management Technologies

Emerging Innovations in Cooling Techniques

The future of thermal management in electronics is as exciting as it is cool (pun intended). Innovations on the horizon promise to redefine our approach to cooling, with technologies like electrohydrodynamic cooling, which uses electric fields to move heat, and phase change materials that absorb heat by transitioning between solid and liquid states. These cutting-edge techniques offer a glimpse into a future where electronics can self-regulate their temperatures, akin to living organisms adapting to their environments.

The Evolution of Materials and Design Approaches

As we look ahead, the evolution of materials and design approaches holds the key to the next generation of thermal management solutions. Nano-fluids, with their enhanced thermal properties, are set to revolutionize cooling systems, while 3D printing offers new possibilities for creating complex heat dissipation structures that were once impossible. The marriage of these advanced materials with innovative design philosophies will pave the way for electronics that are not only more powerful but also cooler by design, ensuring that the future of our devices is as bright as it is cool.

Practical Tips for Electronics Engineers and Designers

Checklist for Thermal Management in PCB Design

Hey there, electronics wizards! Ready to make your next PCB project as cool as the other side of the pillow? Here’s a quick checklist to ensure your design doesn’t get too hot to handle:

- Start with Simulation: Before you solder anything, use thermal simulation software. It’s like having a crystal ball that shows potential hot spots.

- Mind the Materials: Choose PCB materials with good thermal conductivity. Think of it as picking the right sportswear for a workout – you want something that wicks away sweat, or in this case, heat.

- Utilize Thermal Vias: These are essentially heat escape hatches for your PCB. Place them strategically to help transfer heat away from critical components.

- Incorporate Heat Sinks: Attach these lifesavers to heat-generating components. They’re like mini air conditioners, keeping things cool.

- Consider the Layout: Arrange components thoughtfully. Allow breathing room for high-power parts to avoid creating a mini sauna.

Common Mistakes to Avoid in Heat Management

Avoiding common pitfalls can be the difference between a smooth-running device and a hot mess. Remember:

- Don’t overcrowd components; they need personal space to stay cool.

- Skipping thermal testing is like flying blind. Always test before you finalize.

- Underestimating ambient conditions can lead to overheating. Design for the worst-case scenario, not the best.

Conclusion: The Strategic Importance of Thermal Management

Summarizing Key Takeaways

So, we’ve journeyed through the hot topic of thermal management in electronics design, uncovering its critical role in ensuring our devices run efficiently, reliably, and for longer. Remember, managing heat is not just about preventing gadgets from becoming too hot to handle; it’s about safeguarding the heart of our electronics, ensuring they can keep up with our demands and stand the test of time.

The Future of Electronics Design and Thermal Efficiency

Looking ahead, the path of electronics design is unmistakably intertwined with the quest for superior thermal management solutions. As we push the limits of technology, creating more powerful and compact devices, the importance of innovative cooling strategies and materials becomes ever more apparent. The future beckons with the promise of devices that not only perform exceptionally but also manage heat so efficiently, you’d hardly know it was there. For electronics engineers and designers, the challenge is clear: embrace the heat, manage it wisely, and let it propel us towards a future where technology’s potential is fully realized, without getting burned.

0 Comments