Selecting the right PCB manufacturer is a pivotal step in turning your innovative idea into a tangible, market-ready product. Whether you’re a startup or an individual with a groundbreaking proof of concept, understanding the ins and outs of PCB manufacturing will guide you in making an informed decision that aligns with your project’s requirements.

Understanding PCB Manufacturing

What is a PCB?

A Printed Circuit Board (PCB) is the backbone of most electronic designs. It’s essentially a platform that connects various electronic components using conductive tracks and pads. Imagine it as the nervous system of any electronic device, coordinating and controlling the interactions between different parts.

The Role of a PCB in Electronics Design

In electronics design, a PCB ensures the precise operation of your device by facilitating the correct layout and connection of components. It’s not just about connecting A to B; it’s about ensuring your device works efficiently and reliably under various conditions. Choosing the right PCB manufacturer, therefore, becomes crucial, as it directly impacts the performance and reliability of your product.

Key Factors to Consider When Choosing a PCB Manufacturer

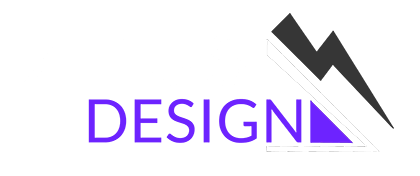

Manufacturing Capabilities and Specialisations

What can your chosen manufacturer really do for you? It’s essential to assess their capabilities, such as the types of PCBs they can produce (single-sided, double-sided, multilayer), and their specializations. Do they cater to small-scale projects or are they equipped for mass production? Knowing this will help you match their strengths to your project’s specific needs.

Quality Certifications and Standards

Quality cannot be overstated. Look for PCB manufacturers who adhere to internationally recognized standards, such as ISO 9001 or UL certification. These certifications are not just fancy numbers; they are a testament to a manufacturer’s ability to meet rigorous quality and reliability standards, ensuring your product performs well in the hands of your customers.

Turnaround Times and Scalability

Time is money, right? In the fast-paced world of product development, how quickly a manufacturer can turn your concept into a full-fledged product is critical. Additionally, consider their scalability. Can they handle your project as it grows from prototype to full-scale production without a hitch?

Assessing the Technical Expertise of a PCB Manufacturer

Importance of Technical Support in PCB Manufacturing

When issues arise—and they likely will—you’ll want a PCB manufacturer with a proactive technical support team. A manufacturer with knowledgeable, accessible support can significantly smooth out the inevitable bumps in the development process, helping you keep your project on track.

Evaluating the Technical Resources Available

Does the manufacturer stay updated with the latest technology and practices in PCB design? Their ability to offer cutting-edge solutions can be a game-changer, ensuring your product not only meets current market standards but sets you apart from competitors. After all, the right manufacturer should make your journey from concept to production as seamless as possible.

By considering these sections, you’ll be better equipped to choose a PCB manufacturer who can turn your vision into reality, ensuring quality, efficiency, and innovation in your product development cycle.

Cost Considerations in PCB Manufacturing

Understanding Pricing Structures

Have you ever wondered why PCB manufacturing quotes can vary so much? It’s crucial to understand the pricing structures to ensure you’re getting the best deal without compromising on quality. Many manufacturers offer a breakdown of costs, including materials, production, and assembly. Make sure to ask about setup fees or any hidden costs that might sneak up on you. After all, knowing the full picture helps you budget effectively, doesn’t it?

Balancing Cost with Quality and Efficiency

Finding the sweet spot between affordability, quality, and efficiency is key. It’s like balancing a seesaw – lean too much on cost-saving, and you might compromise on quality. Conversely, high-end options aren’t always necessary. Aim for a manufacturer who offers competitive pricing while maintaining high standards in quality and delivery efficiency.

The Importance of Prototyping in PCB Design

How Prototyping Can Save Time and Money

Did you know that investing in prototyping could actually save you money down the line? It allows you to test and refine your PCB design, catching costly errors before they become full-scale production nightmares. Think of it as the dress rehearsal before the big show – essential and incredibly valuable.

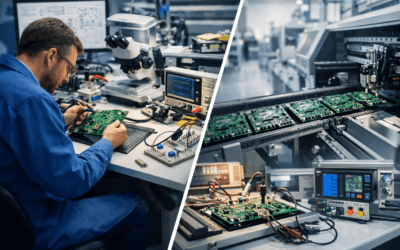

Selecting a Manufacturer with Prototyping Services

Choose a PCB manufacturer that offers comprehensive prototyping services. This not only streamlines the process but also keeps all your development under one roof, reducing the likelihood of errors and miscommunication. A good manufacturer will help you navigate the prototyping phase with ease, ensuring your final product is exactly what you envisioned.

The Impact of Location on Your Choice of PCB Manufacturer

Domestic vs. International Manufacturers

Choosing between a domestic and an international PCB manufacturer can feel a bit like selecting a meal from a vast menu—overwhelming yet critical. Local manufacturers may offer quicker turnaround times and easier communication, which can be a huge relief during crunch times. On the other hand, international options might provide cost benefits but come with their own set of challenges such as shipping delays or language barriers. What’s most important to your project’s timeline and budget?

Considerations for Shipping and Handling

Never underestimate the impact of shipping on your overall costs and project timeline. International shipping not only adds a significant chunk to your expenses but can also introduce unexpected delays. Always factor in these aspects when deciding on a manufacturer’s location. It’s like planning a trip; you wouldn’t start without considering the travel time and costs, right?

Sustainable and Ethical Manufacturing Practices

Importance of Environmental Compliance

In today’s eco-conscious market, aligning with a PCB manufacturer that prioritizes sustainability isn’t just good ethics—it’s good business. Manufacturers who adhere to strict environmental regulations demonstrate a commitment to more than just their bottom line. They show foresight and responsibility, qualities that reflect well on your product as well.

Ethical Practices in the Electronics Manufacturing Industry

Similarly, ethical manufacturing practices are becoming a deciding factor for many businesses. Working with a manufacturer that ensures fair labour practices and maintains a safe working environment does more than ease your conscience. It builds trust and reliability in your brand, turning your product into a beacon of integrity in a competitive market.

How to Get Started with a PCB Manufacturer

Steps to Initiate a Partnership

Ready to take the leap? Starting a partnership with a PCB manufacturer is much like beginning any significant relationship—it should begin with clear communication and set expectations. First, present your project details and expectations clearly. Then, discuss timelines, budgets, and any specific requirements you have. It’s about laying down the foundation for a successful collaboration.

Preparing Your Design Specifications

Before you approach a manufacturer, ensure your design specifications are as detailed as possible. This includes everything from the type of PCB you need, the materials preferred, expected functionalities, and compliance with certain standards. Think of it as giving a tailor precise measurements—doing so increases the chances that the final product will fit perfectly.

By addressing these considerations, you can approach choosing a PCB manufacturer with confidence and clarity, ensuring that the partnership you forge will support your project’s needs and help bring your innovative product to life with efficiency and integrity.

Final Tips Before Making Your Decision

Checklist for Choosing a PCB Manufacturer

Before you seal the deal with a PCB manufacturer, let’s run through a quick checklist. Have you verified their certifications and inspected their manufacturing facility, either virtually or in person? Did you check customer testimonials and review sample products? And importantly, have you discussed and understood their failure and return policies? This checklist isn’t just a formality; it’s your assurance that you are choosing a reliable partner who meets your specific needs in electronics design and manufacturing.

Common Mistakes to Avoid

It’s easy to get caught up in the excitement of seeing your product come to life, but here are some pitfalls to steer clear of: Don’t prioritize price over quality—cheaper can often cost more in the long run due to reworks and failures. Avoid vague communication; ensure every specification and expectation is clear and understood by both parties. And finally, don’t forget to plan for post-production support. How will this manufacturer support you once the initial batch is completed? Avoiding these common mistakes can save you not just time and money, but also a lot of stress.

Wrapping up, choosing the right PCB manufacturer is crucial to the success of your product. It’s about finding a balance between cost, quality, and efficiency while ensuring they align with your business ethics and production needs. Take your time, do your homework, and choose a partner who will not just manufacture your PCBs but will also support your vision of bringing something new and exciting to the market.

0 Comments