Introduction to PCB Design and AI

What is PCB Design?

Printed Circuit Boards (PCBs) are the backbone of electronic devices, connecting components with precision to ensure functionality and reliability. These boards are not just physical entities; they’re the canvas where electronics meet innovation. The process of designing PCBs has evolved, from manual drawings to sophisticated software that handles intricate circuits. But what happens when AI steps into the picture?

The Rise of AI in Engineering

AI is no longer just a buzzword; it’s a revolutionary force across various sectors, engineering included. In PCB design, AI’s role is becoming increasingly significant, making processes faster, more efficient, and less prone to errors. But how exactly is AI integrating into this field? It’s about more than just automation; it’s about smart automation that adapts and learns. Imagine a world where AI not only designs circuits but anticipates future failures and suggests improvements before the first prototype is even printed.

Current Trends in PCB Design

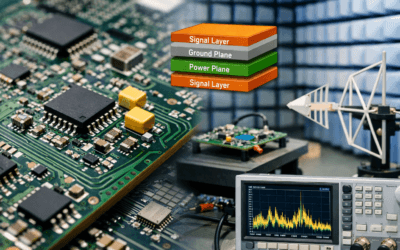

Overview of Modern PCB Design Techniques

Today’s PCB design is heavily reliant on advanced software tools that streamline the creation of complex multi-layer boards. Technologies like HDI (High Density Interconnect) and flexible PCBs are becoming commonplace, pushing designers to innovate continually. With the integration of software, the complexity that used to intimidate beginners is now more manageable—thanks to intuitive interfaces and predictive design capabilities.

Role of Software Tools in PCB Design

The role of software in PCB design cannot be overstated. From schematic capture to board layout and simulation, software tools are indispensable. They provide a digital environment where mistakes can be undone with a simple click, unlike the manual processes of old. But here’s where AI can play a pivotal role: by integrating learning algorithms, these tools can now offer recommendations based on vast datasets of previous designs, essentially becoming smarter with every circuit designed.

How AI is Influencing PCB Design

AI-driven Automation in PCB Layout

Automation in PCB design isn’t new, but AI-driven automation is a game changer. It’s not just about placing tracks on a board; it’s about optimising the entire layout for performance while minimising waste and cost. AI algorithms can analyse hundreds of design rules and apply them in seconds, a task that would take humans significantly longer. This isn’t just efficiency; it’s transformation.

Machine Learning for Error Detection

One of the most critical stages in PCB design is error detection. Traditionally, this involves a manual check—tedious and prone to oversight. Enter machine learning. By training on thousands of successful (and unsuccessful) PCB designs, AI can spot potential issues that even the most experienced designers might miss. What does this mean for the industry? Fewer prototype iterations, reduced costs, and a faster time-to-market. But more importantly, it means that PCBs can be trusted to perform as expected in critical applications, from medical devices to aerospace engineering.

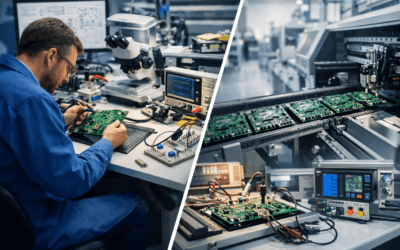

AI Innovations Transforming PCB Prototyping

Speed and Precision in Prototyping with AI

Ever wondered how a world would look where prototype development doesn’t take weeks but merely days or even hours? That’s not a far-off dream—it’s rapidly becoming the new norm with AI in PCB design. AI doesn’t just speed things up; it enhances the precision of each prototype. By predicting and rectifying potential issues before they manifest in the physical model, AI ensures that each iteration is closer to perfection. This means fewer cycles and better outcomes. For engineers, this transition means shifting from hands-on tweaking to strategic oversight, where they guide the creative capabilities of AI rather than control every minute detail.

AI Success Stories in PCB Design

Take, for example, a recent project where AI was utilised to redesign a power supply board for a high-performance computer. The AI system not only optimised the layout for improved heat dissipation but also reduced electromagnetic interference—a double win for performance and reliability. This isn’t just tweaking; it’s about reimagining design parameters for optimal outcomes. Such success stories aren’t just impressive—they’re paving the way for a new era in electronics design.

AI and Electronics Design Simulation

Enhancing Simulation Accuracy with AI

Simulation is a critical tool in PCB design, allowing engineers to anticipate performance and pinpoint potential problems. But what happens when AI gets involved? Simulations become not only faster but smarter. AI algorithms can model scenarios with complex variables that would take humans considerable time to configure. This means designs can be tested under a wider range of conditions to ensure robustness and reliability. It’s like having a crystal ball, but one that’s powered by data and analytics.

Predictive Modeling in Electronics Design

AI’s ability to predict outcomes is perhaps its most tantalising promise. By learning from past designs, AI can predict how slight changes in layout or materials affect performance, longevity, and compliance with regulatory standards. Imagine designing a PCB and knowing in advance how it will perform over its lifecycle, under various stress conditions. That’s the power of AI-driven predictive modeling, transforming guesswork into informed decision-making.

The Challenges of Integrating AI with PCB Design

Technical Challenges and Solutions

Integrating AI into established systems is no small feat. It involves not only technical recalibrations but also a cultural shift within organisations. One major hurdle is data—the fuel for any AI engine. Ensuring data quality and relevance is paramount. Another challenge is the integration of AI tools with existing CAD systems, which often requires significant software development and adjustments. However, solutions are emerging. For instance, bespoke AI plugins for popular design software are being developed to bridge this gap, allowing for a smoother transition and immediate enhancements in design efficiency.

Ethical Considerations in AI Deployment

As AI takes on more responsibility in PCB design, questions about ethics arise. Who is accountable when an AI-designed PCB fails? How do we ensure that AI decisions are fair and do not inadvertently introduce biases into designs? Addressing these questions requires transparent AI processes and standards that govern AI’s role in design—ensuring that AI acts as an empowering tool for engineers, not a substitute. This ethical framework isn’t just necessary; it’s crucial for maintaining trust in the technologies we rely on.

Future Outlook: What’s Next for PCB Design with AI?

Predictions for Future Technologies

As we peer into the crystal ball of PCB design, the influence of AI not only looks set to grow, but to redefine the playing field. What can we expect? For starters, AI is poised to enhance collaborative robotics in the manufacturing of PCBs, enabling more precise and faster production lines. Additionally, the advent of quantum computing offers tantalising possibilities for solving complex electronic design challenges that current technologies struggle with. Can you imagine AI algorithms that design circuits optimised for quantum environments? It’s not just science fiction—it’s the next frontier.

Preparing for an AI-Driven Engineering Future

So, how can today’s electronics engineers gear up for this AI-driven future? Continuous learning is key. Keeping abreast of AI advancements and integrating new software tools into the design process will be crucial. Moreover, as AI becomes more prevalent, engineers will need to pivot from being purely design-focused to becoming stewards of AI, guiding its decisions to ensure they meet the stringent requirements of modern electronics. This shift might seem daunting, but it’s also incredibly exciting. It’s about becoming part of a new era of design that harnesses the power of AI to create innovations previously thought impossible.

Conclusion

Summary of AI’s Impact on PCB Design

Throughout this exploration of AI in PCB design, it’s clear that AI is not just changing the way we design—it’s revolutionising it. From automating tedious tasks to predicting future failures, AI empowers engineers to achieve more accurate, reliable, and innovative designs. The journey from traditional design practices to AI-integrated methods symbolises a significant leap forward in engineering capabilities, pushing the boundaries of what’s possible in electronics design.

Final Thoughts and Future Articles

As we wrap up this initial foray into the future of engineering with a focus on PCB design and AI, remember that this is just the beginning. The landscape of engineering is evolving at an unprecedented pace, driven by advancements in AI. Stay tuned for future articles where we’ll delve deeper into specific AI technologies, their applications in electronics design, and how they’re shaping the industry. For the curious engineer, the future isn’t just coming; it’s already here, and it’s electrifying.

By embracing AI, engineers are not just keeping up with the times; they are actively pushing the envelope, driving innovation and ensuring that the electronics at the heart of modern technology are smarter, safer, and more efficient. The road ahead is as exciting as it is challenging, and it’s laden with opportunities to redefine what it means to be at the cutting edge of technology.

0 Comments