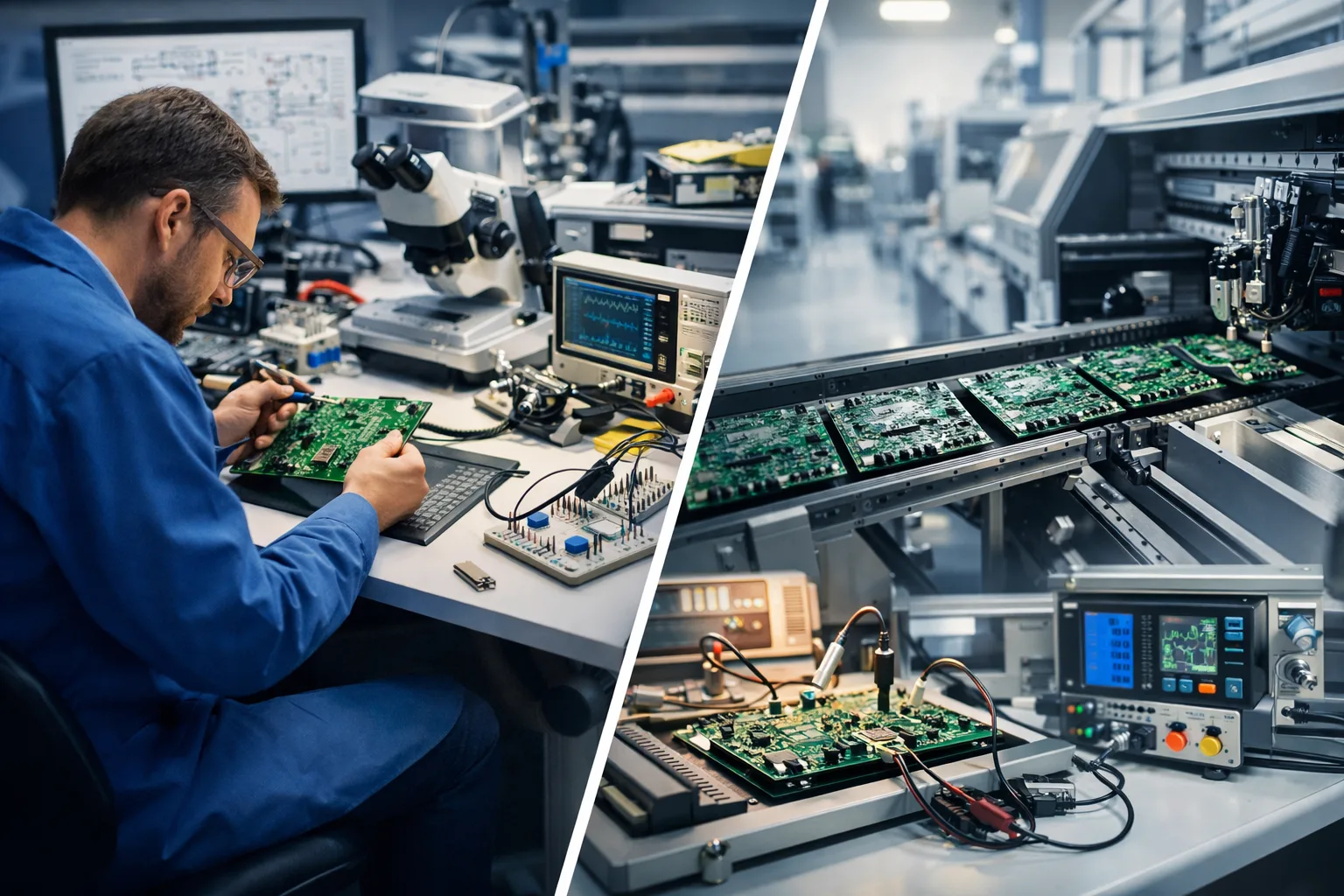

Moving from prototype to production is where most electronics projects either scale successfully — or quietly stall.

A working prototype proves your idea functions. It does not prove it can be manufactured reliably, profitably or at scale. That transition is where margins disappear, timelines stretch and technical debt becomes expensive.

If you’re investing in electronics design and electronics development, you need a deliberate strategy to remove risk early — not react to it later.

Here’s how to do it properly.

Understanding the Real Risks in Electronics Development

Most founders and product teams underestimate where risk actually lives.

It isn’t usually the visible stuff. It’s rarely the obvious schematic error. The real damage comes from overlooked secondary risks that compound during scaling.

Why Most Electronics Projects Fail Before Production

Common failure patterns include:

Prototypes built without manufacturing constraints in mind

Component choices that cannot scale beyond small batches

No defined compliance pathway

Firmware written purely for demonstration

Cost targets considered too late

By the time these surface, redesign is inevitable — and expensive.

Hidden Technical vs Commercial Risks

Technical risks:

Thermal instability

EMC failures

Power integrity issues

Firmware instability

Commercial risks:

BOM cost misalignment

Long lead-time components

Regulatory delays

Low manufacturing yield

If you are not actively managing both categories from day one, you are gambling.

1. Defining Clear Product Requirements Before Electronics Design Begins

Poorly defined requirements create 80% of downstream issues.

You cannot “iterate your way” out of structural ambiguity.

Translating Business Goals into Engineering Specifications

If your goal is market penetration, your electronics development strategy will look different than if your goal is premium differentiation.

Every design decision must connect back to:

Target cost

Target margin

Expected volumes

Operating environment

Regulatory markets

Lifecycle expectations

Engineers need measurable constraints, not vague ambition.

Avoiding Scope Creep and Feature Bloat

Startups especially overload first-generation hardware.

Every additional feature increases:

Firmware complexity

Validation time

Certification risk

Manufacturing cost

Failure points

Gen-1 hardware should prove market fit and production viability — not showcase every future idea.

2. Smart Electronics Design for Manufacturability (DFM)

Designing something that works is baseline competence.

Designing something that can be manufactured reliably at volume is professional discipline.

Designing for Assembly, Test and Scalability

Good DFM considers:

PCB panelisation strategy

Assembly tolerances

Connector orientation

Test-point accessibility

Enclosure alignment

Automated optical inspection compatibility

If you ignore these during prototyping, your production yield will punish you.

Component Selection Strategy for Longevity

Selecting the cheapest part today can cost you requalification tomorrow.

Avoid:

Single-source components

End-of-life risk parts

Unproven suppliers

Long lead-time bottlenecks

Design with lifecycle in mind. Not just unit cost.

3. Prototyping with Purpose: Building to Learn, Not Just to Demo

Not all prototypes are equal.

Functional vs Engineering vs Production Prototypes

Functional prototype: proves core concept

Engineering prototype (EVT): validates design integrity

Production validation (DVT/PVT): validates manufacturing readiness

If you treat a demo unit like a production reference, you’re setting up failure.

What Your Prototype Must Validate

Your electronics prototyping stage should answer:

Does it survive real-world conditions?

Does power management behave under load?

Is thermal behaviour predictable?

Is firmware robust over extended operation?

Can it be assembled consistently?

If these questions remain unanswered, you are not ready to scale.

4. De-Risking Hardware Architecture Early

Architecture mistakes are the most expensive to correct.

Modular vs Custom Architecture Decisions

Modular designs reduce early risk and speed prototyping.

Custom integrated designs reduce cost and improve performance at scale.

Choose based on:

Expected volumes

Margin sensitivity

Upgrade roadmap

Time-to-market pressure

Short-term speed often conflicts with long-term cost optimisation. Make that trade consciously.

Managing Power, Thermal and EMC Risks

These three areas kill products late.

Power integrity failures cause instability.

Thermal issues reduce lifespan.

EMC failures block certification.

Design for worst-case conditions — not lab conditions.

5. Firmware and Software Integration Strategy

Hardware rarely fails alone.

Hardware–Firmware Co-Development

Electronics design and firmware development must evolve together.

Late firmware integration reveals:

Timing errors

Peripheral conflicts

Power sequencing flaws

Memory limitations

Parallel development reduces integration shock.

Planning for OTA Updates and Future Features

If your product connects, assume it will need:

Security updates

Feature expansion

Bug fixes

Design memory, processing headroom and architecture accordingly.

Future-proofing is cheaper at design stage than post-launch redesign.

6. Supply Chain Strategy from Day One

Supply chain risk is no longer theoretical.

Avoiding Single-Source Component Risk

Single-source ICs are dangerous.

Where possible:

Qualify alternates

Use widely adopted chipsets

Check lifecycle commitments

Resilience must be engineered into the BOM.

Forecasting Lead Times and Obsolescence

Your electronics development roadmap must align with:

Forecasted production volumes

Component allocation risk

Long-term supplier stability

Ignoring supply realities will stall scaling.

7. Regulatory and Compliance Planning

Certification is not a formality.

CE, UKCA, FCC and Industry-Specific Certifications

Depending on target markets, your product may require:

CE marking

UKCA compliance

FCC certification

Industry-specific approvals

Each has design implications.

Designing for Compliance Rather Than Testing into Compliance

Testing into compliance is reactive and costly.

Instead:

Design PCB layout for EMC control

Use shielded enclosures where needed

Plan isolation distances early

Compliance should validate design — not correct it.

8. Testing Strategy That Prevents Costly Redesigns

Testing is insurance.

Environmental, Stress and Reliability Testing

Before production, validate:

Temperature cycling

Vibration resistance

Long-duration runtime

Power surge tolerance

Field failures are far more expensive than lab testing.

Automated Test Fixtures and Production QA

Scalable electronics development includes:

Bed-of-nails test fixtures

Firmware flashing automation

End-of-line functional validation

Manual testing does not scale economically.

9. Cost Engineering and BOM Optimisation

If you do not design to cost, cost will design your margin.

Designing to Target Cost

Start with:

Target retail price

Channel margin

Manufacturing cost ceiling

Then engineer backwards.

Volume Breakpoints and Margin Protection

Component pricing shifts dramatically with volume.

Plan for:

Early low-volume builds

Mid-scale runs

Full production ramp

Your pricing model must account for this evolution.

10. Transitioning from Prototype to Pilot Build

The pilot run is your truth moment.

What a Pilot Run Should Prove

It should validate:

Assembly consistency

Yield rates

Cycle times

Documentation accuracy

Firmware flashing reliability

If yield is below acceptable threshold, scaling will magnify the problem.

Common Mistakes During First Production Runs

Incomplete documentation

Missing revision control

No structured defect logging

Underestimating firmware stability issues

Production is unforgiving. Preparation reduces shock.

11. Working with Contract Manufacturers Effectively

Your manufacturing partner is not a magician.

Selecting the Right Manufacturing Partner

Look for:

Experience in similar product categories

Transparent costing

Engineering support capability

Scalable capacity

Cheapest rarely means safest.

Communication, Documentation and Version Control

Professional electronics development requires:

Controlled BOM revisions

Clear assembly drawings

Defined test procedures

Formal change management

Verbal agreements collapse under scale.

12. Scaling Production Without Losing Quality

Growth introduces variability.

Process Control and Yield Management

Monitor:

Defect rates

Rework percentage

Field return data

Supplier quality trends

Small inefficiencies compound at scale.

Managing Field Returns and Feedback Loops

Returns are data.

Feed insights back into:

Hardware revisions

Firmware updates

Supplier adjustments

Scaling is iterative, not static.

13. Building an Electronics Development Roadmap for Growth

If you treat each product as isolated, costs compound.

Planning Gen-2 Before Gen-1 Ships

While Gen-1 enters production, start:

Cost reduction analysis

Feature feedback collection

Platform architecture review

This shortens future cycles dramatically.

Platform Strategy vs One-Off Products

Platform-based electronics design allows:

Shared firmware

Shared power architecture

Shared PCB frameworks

Reduced NRE costs

One-off products burn capital.

Think in systems, not units.

14. Choosing the Right Electronics Development Partner

The wrong partner increases risk quietly.

What Established Businesses Should Look For

You need:

Process discipline

Documentation maturity

Regulatory experience

Supply chain strategy

Not just engineers who can build a prototype.

What Startups Must Get Right the First Time

You cannot afford:

Multiple hardware spins

Certification failures

BOM cost misalignment

Your first production attempt must be strategically sound.

15. Final Thoughts: Engineering Confidence into Production

Moving from prototype to production is not a linear progression. It is a risk-reduction exercise.

Strong electronics design is only the beginning. Mature electronics development anticipates scaling pressures long before they appear.

If you approach prototyping as experimentation without production intent, you will pay for it later.

If you approach development with manufacturing, compliance, supply chain and lifecycle in mind from day one — scaling becomes predictable.

And predictability is what investors, operations teams and customers actually value.

0 Comments