Welcome to the exciting world of PCB prototyping, a pivotal phase in the journey of transforming your innovative ideas into tangible, functional products. Whether you’re at the helm of a startup, part of a company looking to outsource, or an individual armed with a proof of concept, grasping the intricacies of PCB prototyping is paramount. This guide is meticulously crafted to demystify the process, making it accessible and understandable for those without an engineering or design background.

Understanding PCB Prototyping

Definition and Basics

PCB prototyping is the art and science of creating a physical sample of your electronic circuit, allowing you to test and validate your design in the real world. This process is indispensable across a myriad of industries, ranging from consumer electronics to medical devices, as it paves the way for identifying potential issues and making necessary adjustments. The end goal? Ensuring your product functions flawlessly, saving valuable time, and significantly cutting down costs in the long run.

Applications in Various Industries

From the latest smartphones to life-saving medical equipment, PCBs are the unsung heroes behind the scenes. In the automotive industry, for instance, prototypes are used to test safety systems and enhance performance. In consumer electronics, they ensure that your gadgets are compact yet powerful. Understanding these applications provides a window into the vast potential of PCB prototyping.

Benefits for Product Development

Embarking on the prototyping journey offers a treasure trove of benefits. It’s a proactive step towards validating your design, catching errors early, and refining functionality. It’s about making informed decisions and paving a smoother path to mass production. In essence, it’s an investment in the future success of your product.

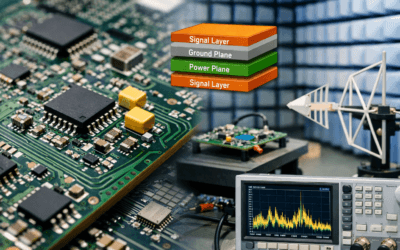

The PCB Design Process

Initial Concept and Sketching

Every groundbreaking product starts with an idea. Transforming this idea into a physical product begins with sketching out your concept, laying the groundwork for what’s to come. This is the stage to brainstorm, to be creative, and to start visualizing your product.

Software Tools for PCB Design

Entering the digital realm, there are a plethora of software tools designed to bring your sketches to life. For those just starting out, there are beginner-friendly platforms that come with extensive tutorials and community support, ensuring a smooth learning curve. On the other end of the spectrum, we have professional-grade tools like Altium Designer, renowned for its comprehensive features and robust capabilities.

Altium Designer stands out as a leader in the field, catering to professionals who demand precision, efficiency, and a wide array of advanced features. It’s a tool that grows with you, capable of handling complex designs and intricate projects with ease. The key is finding a tool that aligns with your skill level and project requirements, ensuring that you have the support and functionality you need to bring your vision to life.

Tips for Effective PCB Design_

Navigating the design process can be daunting, but with a few tips and tricks, you can set yourself up for success. Focus on simplicity, strive for efficiency, and don’t shy away from seeking advice or using online resources. Remember, a well-executed design is a critical step towards a successful prototype.

Choosing the Right PCB Prototyping Method

Overview of Different Prototyping Methods

From rapid prototyping that excels in speed to traditional methods known for precision, the world of PCB prototyping is diverse. Each method has its own set of advantages and disadvantages, and understanding these is crucial in making an informed decision.

Pros and Cons of Each Method

Rapid prototyping, for instance, is ideal for quick iterations, allowing you to test and tweak your design in a short timeframe. Traditional methods, on the other hand, might take longer but can offer a higher level of accuracy and finish. Assessing these pros and cons in the context of your project’s specific needs is vital._

Recommendations for Startups_

For startups operating on tight budgets and timelines, finding the right balance is key. Seek out prototyping methods that offer a good compromise between speed, precision, and cost. Don’t hesitate to consult with prototyping services, as their expertise can provide invaluable insights and recommendations.

Cost Considerations in PCB Prototyping

Factors Influencing the Cost

The cost of bringing your PCB prototype to life can be influenced by a myriad of factors, including the complexity of your design, the materials used, and the chosen prototyping method. Understanding these factors allows you to make informed decisions and manage your budget effectively.

How to Optimise Your Budget

To optimise your budget, focus on simplifying your design where possible, and seek out affordable yet reliable prototyping services. Remember, the goal is to strike a balance between cost and quality, ensuring that your prototype meets your requirements without breaking the bank.

Finding Affordable Prototyping Services

Navigating the world of PCB prototyping services can be overwhelming, but with research and due diligence, you can find partners that offer a perfect blend of affordability and quality. Look for services with positive reviews, transparent pricing, and a track record of success with startups.

Common Mistakes and How to Avoid Them

Overview of Frequent Errors

Even with meticulous planning, mistakes can happen. Common pitfalls include design errors, choosing the wrong materials, or miscommunications with your prototyping service. Being aware of these potential issues is the first step towards avoiding them.

Tips for Error-Free Prototyping

To ensure a smooth prototyping process, double-check your design, communicate your requirements clearly, and learn from past mistakes. Don’t hesitate to ask for advice or seek second opinions, as a fresh set of eyes can often spot potential issues that might have been overlooked.

Learning from Mistakes

Embracing mistakes as learning opportunities can transform challenges into valuable lessons. Analyze what went wrong, understand the root cause, and use these insights to refine your approach in future projects.

Case Studies: Successful PCB Prototyping Examples

Startups That Excelled

Drawing inspiration from startups that have successfully navigated the PCB prototyping landscape can provide motivation and practical insights. These companies have managed costs, tackled design challenges, and iterated their way to success, proving that with the right approach, anything is possible.

Lessons Learned

Analysing these success stories reveals common themes and valuable lessons. The importance of thorough testing, the benefits of iterative design, and the value of a strong partnership with your prototyping service are just a few of the takeaways.

How They Managed Costs and Design Challenges

Understanding how these startups managed their budgets and overcame design challenges provides a roadmap for your own journey. It’s about being strategic, resourceful, and resilient, qualities that are essential for any entrepreneur.

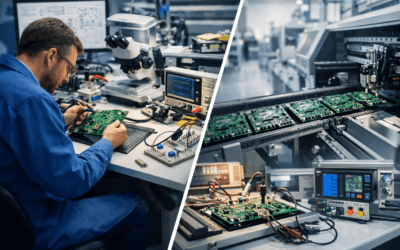

Tips for Collaborating with PCB Prototyping Services

Finding the Right Partner

The success of your PCB prototyping project is heavily dependent on finding the right partner. Look for services with experience in your industry, positive customer reviews, and the ability to communicate effectively.

Communicating Your Needs Clearly

Clear communication is paramount. Ensure that your requirements, expectations, and timelines are understood, leaving no room for ambiguity. A clear and concise brief can make all the difference.

Ensuring Quality and Timeliness

Quality and timeliness are non-negotiable. Work with your prototyping service to establish quality benchmarks and realistic timelines, ensuring that your project stays on track from start to finish.

Future Trends in PCB Prototyping

Technological Advancements

The landscape of PCB prototyping is constantly evolving, driven by technological advancements and innovation. Staying abreast of these trends ensures that you remain competitive and well-positioned to leverage new opportunities.

Industry Shifts

Changes in the industry, from the adoption of new materials to shifts in manufacturing practices, can have a profound impact on PCB prototyping. Being adaptable and open to change is crucial in navigating these shifts successfully.

What This Means for Startups

For startups, these trends represent both challenges and opportunities. Embracing change, investing in continuous learning, and staying ahead of the curve are key strategies for success in this dynamic field.

Conclusion

In wrapping up this comprehensive guide, it’s clear that PCB prototyping is an invaluable step in the product development journey. For startups and entrepreneurs, it’s a gateway to innovation, a tool for validation, and a means to turn visions into reality. Armed with the right knowledge, tools, and partners, you are well-equipped to navigate this process, setting the stage for success in the competitive world of product development.

0 Comments