In 2025, the electronics industry faces a rapidly evolving regulatory environment. From connected IoT devices to AI-integrated hardware, compliance has never been more critical. Understanding and adhering to global standards such as CE (Europe), FCC (United States), UL (safety certification), and Australian regulations (RCM) is essential for companies aiming to access international markets while ensuring safety, quality, and reliability.

For startups and established manufacturers alike, designing with compliance in mind ensures smoother certification, faster product launches, and greater trust from customers and regulatory authorities.

Understanding Regulatory Compliance in Electronics Design

Regulatory compliance in electronics design refers to ensuring products meet legal, safety, and environmental standards before entering the market. Compliance demonstrates that a product operates safely, avoids interference, and is environmentally responsible.

For manufacturers, compliance is both a strategic and legal necessity. It prevents costly redesigns, legal disputes, and market delays while promoting a culture of responsible innovation.

The Role of Standards in Product Safety and Performance

Standards such as CE, FCC, UL, and RCM set the benchmark for how electronics should perform safely within their intended environments. They also ensure interoperability and protect users from hazards such as electrical shock, fire, or radiation. Compliant design builds consumer confidence and facilitates entry into competitive markets.

CE Marking: Gateway to the European Market

The CE marking is a mandatory certification for electronics sold in the European Economic Area (EEA). It signifies that the product meets EU safety, health, and environmental protection requirements. For 2025, the EU continues to strengthen its compliance regime, particularly around sustainability and cybersecurity.

Key CE Directives Relevant to Electronics

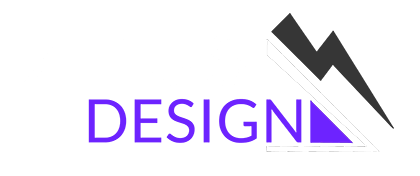

The most critical directives for electronics manufacturers include:

- EMC Directive (2014/30/EU): Ensures electronic devices do not cause or suffer from electromagnetic interference.

- Low Voltage Directive (2014/35/EU): Addresses electrical safety for devices within specific voltage ranges.

- RoHS Directive (2011/65/EU): Restricts hazardous substances such as lead, mercury, and cadmium.

- Eco-Design Directive: Promotes energy efficiency and product recyclability.

In 2025, new amendments reinforce energy labelling, digital product passports, and supply chain transparency, aligning with the EU’s Green Deal.

CE Conformity Assessment and Documentation

To affix the CE mark, manufacturers must:

- Identify applicable directives.

- Conduct testing (self-assessment or via notified bodies).

- Compile a Technical File with schematics, test reports, and risk analyses.

- Draft a Declaration of Conformity (DoC) confirming compliance.

The CE mark is both a legal obligation and a mark of engineering credibility in the EU market.

FCC Compliance: Meeting US Regulatory Standards

In the United States, the Federal Communications Commission (FCC) governs all electronic products that emit radiofrequency energy. Compliance ensures that products do not interfere with communication systems or other devices.

Understanding FCC Part 15 Requirements

The FCC categorises products as:

- Intentional Radiators (e.g. Wi-Fi, Bluetooth, 5G devices).

- Unintentional Radiators (e.g. computers, digital processors).

Products must be tested for radiated and conducted emissions, ensuring they remain within FCC Part 15 limits. Manufacturers must also label products appropriately and maintain testing documentation for inspection.

2025 FCC Updates and Emerging Wireless Technologies

As the US moves deeper into 5G, Wi-Fi 7, and IoT ecosystems, the FCC has refined rules for unlicensed spectrum and cybersecurity obligations. Updated guidance emphasises secure firmware updates, data protection, and resilience against remote exploits—key considerations for connected devices in 2025.

UL Certification: Ensuring Product Safety

Underwriters Laboratories (UL) certification, while voluntary, is highly respected worldwide. It demonstrates that products have undergone independent testing for safety and quality. Many retailers, especially in North America, require UL certification as a condition of sale.

Common UL Standards for Electronics Design

Prominent UL standards relevant to electronics include:

- UL 62368-1: The primary standard for audio/video and IT equipment, focusing on hazard-based safety.

- UL 94: Covers flammability of plastic components used in enclosures and housings.

- UL 2054: Addresses the safety of rechargeable batteries and energy storage systems.

Compliance with UL standards ensures a product’s long-term safety and builds confidence among consumers and distributors alike.

Benefits of Voluntary UL Certification

Although UL certification isn’t mandatory, it enhances market credibility, retailer acceptance, and consumer trust. For startups entering competitive sectors, UL certification can serve as a powerful differentiator and mitigate liability risks.

Australian Regulations: RCM and ACMA Compliance

In Australia, all electrical and electronic devices must comply with Australian Communications and Media Authority (ACMA) and Electrical Regulatory Authorities Council (ERAC) requirements. Products meeting these standards display the Regulatory Compliance Mark (RCM).

Understanding the Regulatory Compliance Mark (RCM)

The RCM combines both electromagnetic compatibility (EMC) and electrical safety compliance. It signifies that a product meets the necessary Australian and New Zealand standards and that the manufacturer is registered with the National Database of Responsible Suppliers.

Key Australian Standards for Electronics Design

Relevant frameworks include:

- AS/NZS CISPR 32: Governs EMC emissions for multimedia equipment.

- AS/NZS 60950.1 and 62368.1: Define electrical safety standards for ICT and AV equipment.

- AS/NZS 4665: Focuses on energy efficiency and eco-design for certain appliances.

The Role of ACMA and ERAC

- ACMA enforces EMC and radio communications requirements.

- ERAC oversees electrical safety standards.

Manufacturers must retain compliance records, product test reports, and labelling details for at least five years after sale. Failure to comply can lead to fines or removal from the market.

Global Harmonisation and Market Access

As global trade expands, harmonisation of compliance standards across regions becomes essential. Many manufacturers aim for unified certification strategies to simplify multi-market access.

Mutual Recognition Agreements (MRAs)

Australia, the EU, and the US participate in Mutual Recognition Agreements, allowing certain test results and certifications from one region to be recognised in another. MRAs help reduce testing duplication, cut costs, and accelerate time-to-market—critical for electronics developers in 2025.

Key Compliance Challenges in 2025

Electronics designers now face increasing pressure to consider not just functionality but also cybersecurity, sustainability, and data protection.

Cybersecurity and Data Protection in Electronics

Regulators worldwide are implementing cybersecurity requirements. The EU’s Cyber Resilience Act (CRA), Australia’s Security of Critical Infrastructure Act, and the FCC’s emerging cybersecurity labelling programme all highlight the growing importance of secure design. Manufacturers must ensure data encryption, secure boot, and robust update mechanisms.

Sustainability and Eco-Design Requirements

Eco-design principles are shaping the next generation of products. Standards now push for repairability, recyclability, and energy efficiency, aligning with sustainability goals under frameworks like the EU Green Deal and Australia’s National Waste Policy Action Plan.

Steps to Achieve Compliance from Concept to Market

Embedding compliance early in product design ensures a smoother path to certification and market approval.

Pre-Compliance Testing and Risk Mitigation

Early-stage pre-compliance testing helps identify potential EMC or safety issues before formal certification. It can drastically reduce project delays and redesign costs.

Documentation and Traceability Best Practices

Maintaining detailed documentation—including risk analyses, test results, supplier declarations, and component traceability—is essential. These records support product recalls, audits, and long-term compliance verification.

Working with Testing and Certification Bodies

Choosing an accredited test laboratory or certification body is key. In Australia, labs accredited under NATA (National Association of Testing Authorities) provide reliable results recognised internationally. Collaborating early ensures testing aligns with technical requirements and reduces project setbacks.

The Cost of Non-Compliance

Non-compliance can result in product recalls, fines, import bans, and brand damage. In Australia, selling non-compliant products can lead to enforcement actions from ACMA or ERAC. Globally, violations can cause distribution delays or permanent bans from key markets—making proactive compliance a financial imperative.

Future Trends in Electronics Compliance Beyond 2025

The future of electronics compliance will be shaped by digitalisation and sustainability. Expect wider use of digital product passports, AI-driven compliance audits, and blockchain-based traceability systems. Moreover, as AI and autonomous electronics mature, regulators will likely introduce new ethical and performance requirements to ensure safe human interaction.

Conclusion: Designing for Compliance and Market Success

In an interconnected global market, compliance is not optional—it’s a competitive advantage. By integrating CE, FCC, UL, and Australian RCM standards from the start, electronics designers can streamline certification, enhance safety, and expand market reach.

As 2025 unfolds, success in electronics design will hinge on the ability to innovate responsibly, combining engineering excellence with rigorous compliance. Companies that embed these principles into their design DNA will lead the next era of sustainable, secure, and globally trusted technology.

0 Comments